Biodegradable Mulch Trial: Report

As a part of our soil health workshop series, we have been putting out trial plots to demonstrate various soil health building practices.

During our most recent training on June 27th we toured our comparison of several different types of row middle mulches.

We compared two biodegradable mulches (Bio360 and and Organix AG), black plastic polyethylene (PE) mulch, compost, straw and bare-ground.

The Bio360 was 0.6mil thick and made up of “Mater-Bi”, a non-genetically modified corn starch plus a polymer. The Organix AG Biodegradable Mulch Film was 0.7mil thick. Neither of these products is approved for organic production. No plastic biodegradable mulch products are currently approved for use in organic cropping systems in the U.S. because currently available products are not completely biobased (USDA 2015) (See more information about biodegradable mulches and the makeup here).

The compost was City of Fayetteville Yard Waste Compost applied to a 1 inch depth on the bed’s surface. Straw was spread to a similar depth.

All of the in-row materials were laid on April 26th in Fayetteville, AR, and planted with sweet corn soon after. A single line of drip tape was run down each row. The corn was irrigated and fertigated weekly.

The corn height and growth in the two biodegradable mulches was similar, however the Organix AG product began to tear sooner than the Bio360 product.

The following pictures were taken on June 27th, about 60 days after the plastic was laid.

Observations

- The standard black plastic mulch had the fewest weeds break through the plastic and the fewest rips and tears, but did still have nutsedge break through the plastic.

- The Bio360 biodegradable mulch had fewer tears and rips than the Organix AG biodegradable mulch, but both had grass and nutsedge break through the plastic.

-

- Purple nutsedge and yellow nutsedge are especially problematic in plasticulture systems because the weeds are capable of penetrating plastic mulch.

- The weedy grass species are not capable of penetrating the plastic mulch directly; instead, they opportunistically emerge where tears occur in the plastic. Tears were more common in biodegradable mulches, and nutsedge more readily pierced the biodegradable mulches

- When considering using biodegradable mulches keep in mind that there is considerable

variability in the durability of different biodegradable mulch products even after

only 60 days.

- We will report back on how well the materials break down over the next few months.

- While the biodegradable mulches were not as effective at supressing weeds compared to the plastic mulch, the corn growth and development were similar between the biodegradable and the plastic mulches.

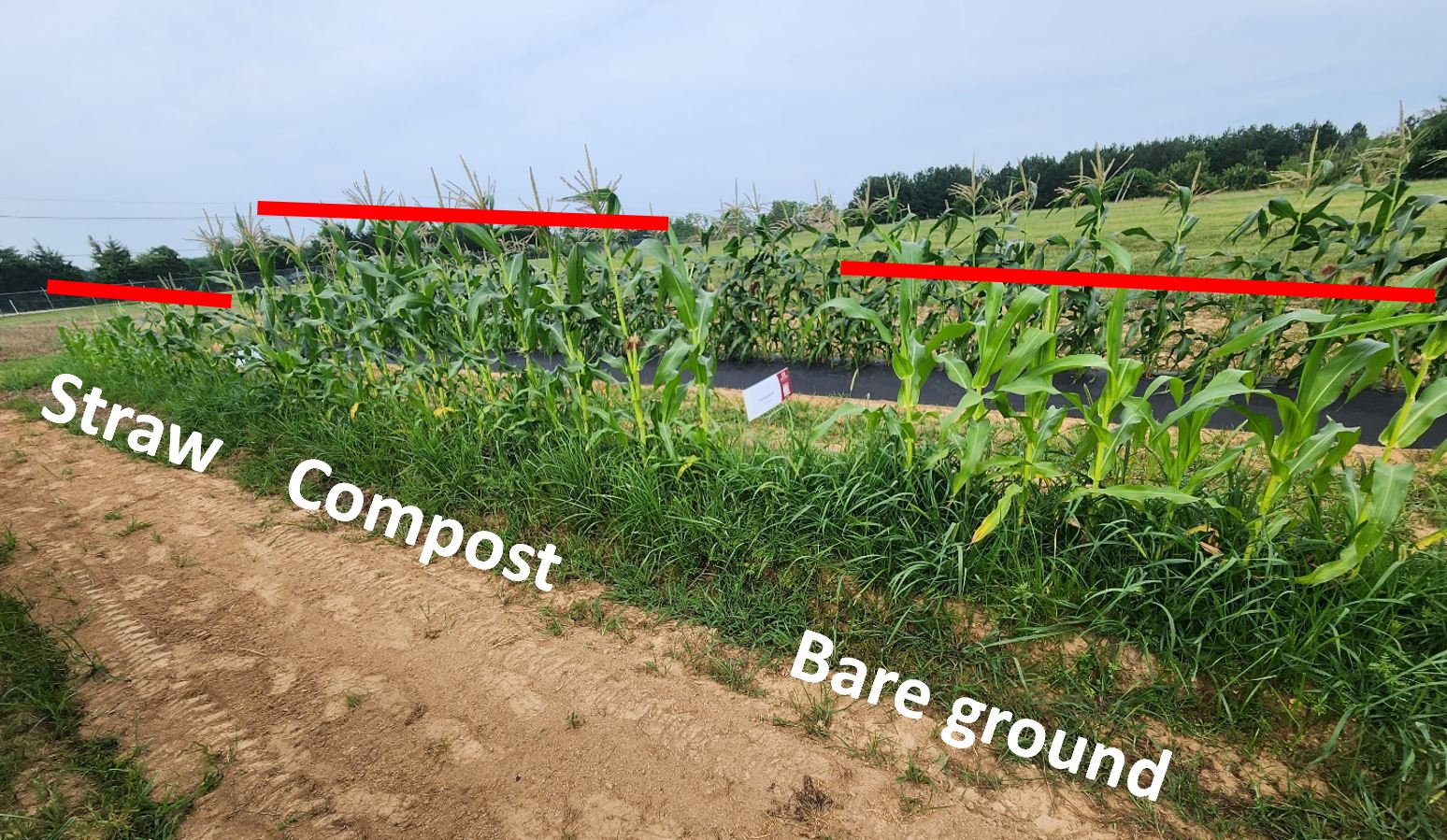

- The row covered with either straw, compost or left bare had the most weed pressure of all the rows. Heavy grass weed pressure was observed on this row. Within this row the corn grew the tallest and was tasseling earlier in the compost section of the row, whereas the corn looked stunted in the straw and bareground sections.

Heavy weed pressure and reduced corn growth were observed where straw was applied or the soil was left bare, compared to where compost was applied to the bed top.

Notice the shorter height of the corn under the compost compared to the biodegradable (Left) and plastic mulch (right in the back). We hypothesize the black mulch products helped warm the soil in late spring which benefited the early planted corn.

These preliminary results do demonstrate that black mulch products, either plastic or biodegradable, can impact crop development timing and contribute to weed suppression compared to bare ground, straw or compost products. The higher cost of biodegradable products may not be currently justified, particularly due to restrictions on their use in organic systems.

Yield Update 8/24/2023

Summary of results

This demonstration highlights the importance of preventative weed management for sweet corn production. In the bareground plot, weeds completely overgrew the corn planting and resulted in a total crop failure. Of the tested mulch treatments, plastic barriers were most effective for weed prevention, followed by compost and straw mulch. These results are reflected in the corn yields during harvest. Conventional plastic had the fewest weeds over the course of the season and produced 180 ears per 100 ft of row (Table 1). The biodegradable mulch options, Bio360 and Organix AG, broke down over the course of the season; and late-emerging weeds interfered with the corn’s growth and yield. Per 100 ft, the Bio360 plot produced 147 ears, and the Organix AG plots produced 133 ears (Table 1). Finally, the compost amended plot yielded 133 ears per 100 ft, and the straw covered plot produced 60 ears per 100 ft. Corn grown on conventional plastic produced as much as 33 to 47 more ears per 100 ft than the Bio360 and Organix AG plots, respectively. Similarly, corn on conventional plastic produced 47 and 120 more ears per 100 ft than compost and straw, respectively.

When translated strictly to yield as pounds per 100 ft, the conventional plastic plot still produced the largest corn yield (Table 2). However, the disparities in yield were smaller than the disparities in number of ears. The Bio360 plot yielded a comparable amount corn (120 lb per 100 foot) to the conventional plastic (129 lb per 100 foot). Though, the Organix AG plot exhibited a reduced yield, producing only 102 lb per 100 foot. Finally, the compost and straw were reduced even further, producing 87 and 35 lb of corn per 100 ft, respectively. The clearest explanation for the disparities in ear count and corn yield are the reduced average ear weights presented in Table 3. An additional confounding factor is that sweetcorn varieties differed among some treatments: ‘Remedy’ was used for the conventional plastic, compost, bareground, and straw plots wile ‘Serendipity’ was used for the Bio360 and Organix AG plots.

It is important to note that in-season weed control is an option when weeds arise, whether it is hand-weeding, cultivation, or the use of herbicides. This demonstration highlights the season-long weed control accomplished by conventional plastic and the need for earlier intervention in other systems. Decision making for weed management strategies should identify which strategies are economically justified and maximize profitability for a grower.

Table 1.

|

Corn variety |

|

weight (lb) |

count |

avg weight |

weight/100 ft row |

count/100 ft row |

|---|---|---|---|---|---|---|

|

Serendipity |

Bio360 |

17.98 |

22 |

0.82 |

120 |

147 |

|

Serendipity |

Organix AG |

15.27 |

20 |

0.76 |

102 |

133 |

|

Remedy |

Bareground |

0 |

0 |

. |

0 |

0 |

|

Remedy |

Compost |

13.12 |

20 |

0.66 |

87 |

133 |

|

Remedy |

Straw |

5.26 |

9 |

0.58 |

35 |

60 |

|

Remedy |

Conventional Plastic |

19.3 |

27 |

0.71 |

129 |

180 |